Nutsche Filters

- Home

- Nutsche Filters

NUTSCHE FILTERS

We have developed and designed our own range of VSK Static Nutsche Filters (NF), Agitated Nutsche Filters (ANF) and Agitated Nutsche Filter Dryers (ANFD) used for solid-liquid separation processes, by filtration under pressure and vacuum drying; in chemical, pharmaceutical, food industry and cosmetics any many others, from pilot to production scale.

Working Principle of the Agitated Nutsche Filter Dryer is described here: ANFD Working Principle | LEHMANN INDUSTRIE.

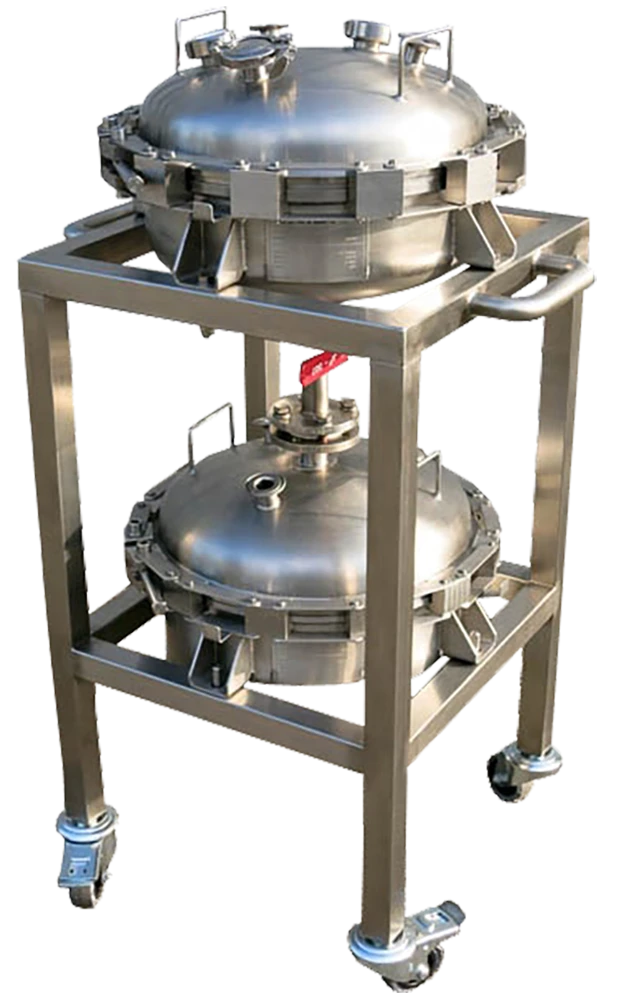

Static Nutsche Filters

A common feature of these filters is the manual emptying of the cake through the upper part of the device, by opening the top lid. Depending on the diameter of the lid, the resulting mass and the type of application, several variants of lid opening are designed.

Agitated Nutsche Filters

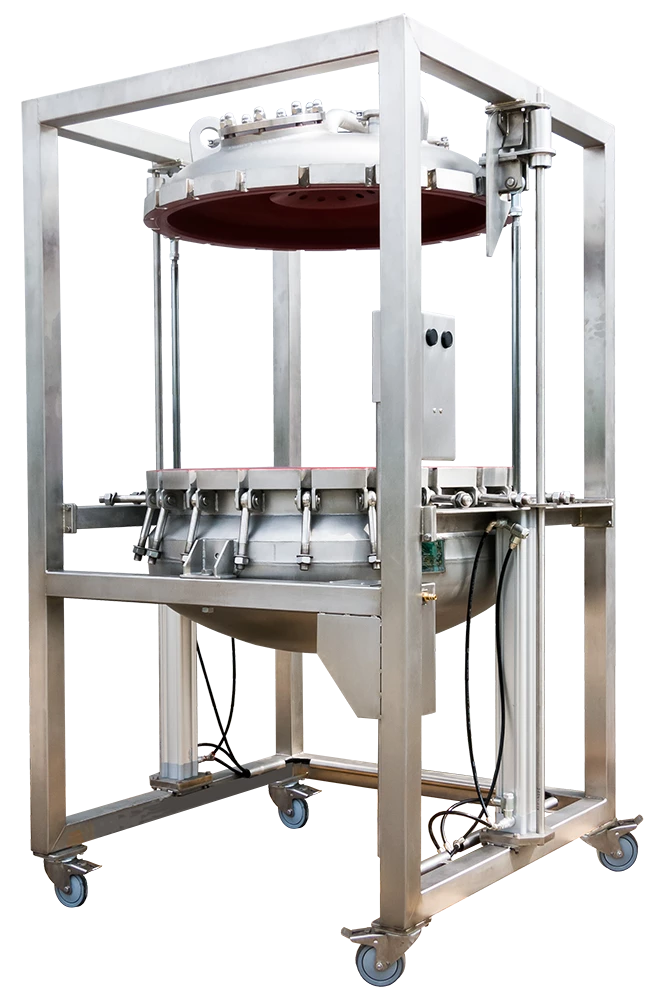

Simple Agitated Nutsche Filters

It is essentially based on a static nusche filter design with a pneumatic lid lift and manual emptying of the cake in the upper part, supplemented by a 2-paddle stirrer with rotation in one direction. Stirring helps the filtration process as well as possible drying of the cake.

Automatic Agitated Nutsche Filters

This most advanced version of the nutsche filter works fully automatic way and consists of the stirrer with J-shaped paddles with alternative rotation (in clockwise direction it smooths, in the counterclockwise direction it ploughs), and helps to evacuate the cake through the side discharge valve. In addition, there is a function of hydraulic lowering of the filter plate.

KEY FEATURES & OPTIONS

- Pressure and atmospheric apparatus for filtration of pharmaceutical and chemical products

- Maximum operating pressure from -1 (vacuum) to 10 bar

- Volumes 5, 10, 25, 50, 100, 250, 500, 1000 liters*

- Perforated filter screen with a ring for filter fabric attachment

- Heated jacket (duplicator)

- Cake washing

- CIP / SIP washing and spraying systems

- CE certificate, PED (2014/68/EU) or ASME U Stamp, ATEX (2014/34/EU)

MATERIAL OF CONSTRUCTION

- Stainless steel (DIN 1.4571, DIN 1.4541, DIN 1.4301, …)

- Nickel, nickel alloy (Hastelloy®)

- PP, PVDF

- Coating (PFA RubyRed®, Halar® E-CTFE)

HEATING

- unheated

- heated jacket (duplicator)

- heating spiral

FILTER SCREEN

- perforated according request

FILTER FABRIC ATTACHMENT

- pressure ring with bayonet

- pressure ring bolted